January 5, 2026

Cleaning to Protect Your Food Production

Craig Nelson, CEO

The Importance of CIP

CIP in a food, dairy, or beverage processing facility is the primary defense against product quality challenges, shelf-life reduction, or even recalls.

So often the remediation for poor CIP designs is to increase CIP times, increase chemicals, and increase wash temperatures. However, these measures only hide the real problems. Soils harborage points hiding bacteria, pathogens, or spores will still exist.

The core principles of trustable CIP:

- CIP flow rates need to flow at 5-6 feet per second

- Flow rates should change if the pipe route is a different size

- Flow routes on each circuit should be timed individually

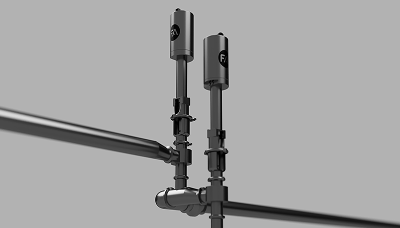

- Every valve seat and stem needs to be moved to clean minor surfaces

- Then times and chemical strength can be dialed in to spec

Flow rates are incredibly important. Five to six feet per second of velocity is the best rate to create turbulence in a pipe circuit for proper friction and washing. In tanks, silos, and other vessels always use the manufacture’s flow rate specification. When the flow is diverted to another route, adjust the flow on the supply pump to match that pipe segment.

Pulsing valves to route the CIP solution through its different paths should be done with diligence. Often, we’ll see valve pulsing done in a standard manner, like one minute each route. This creates a situation where a short routes are washed well, but long segments may be highly under washed. Measure or estimate the length of each route of the circuit. Divide each length by 5-6 feet per second. Make sure each segment is washed 3-4 times for each pulse.

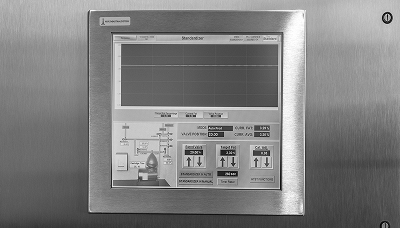

The best CIP systems have feedback on every valve, and valve seats if they are mix proof valves. The software can then report if any device in the CIP circuit didn’t pulse properly.

Trustworthy CIP requires diligence in design, programming and monitoring. When done right it can be the principle protection of your food quality.